Laser Cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists.

- Overview

- Related Products

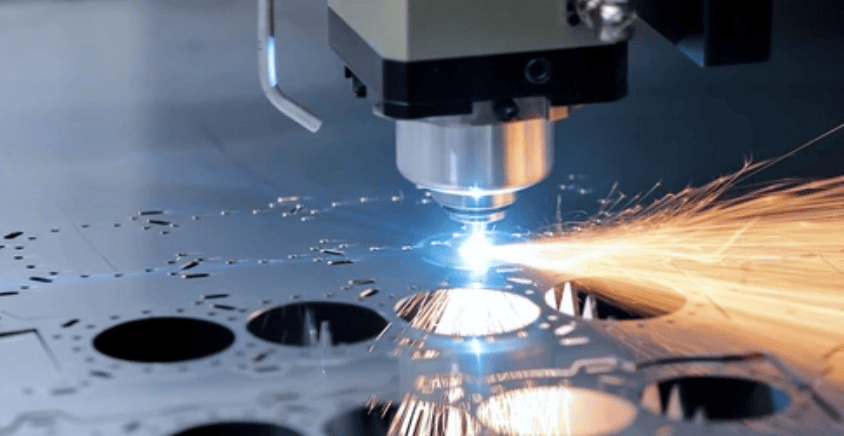

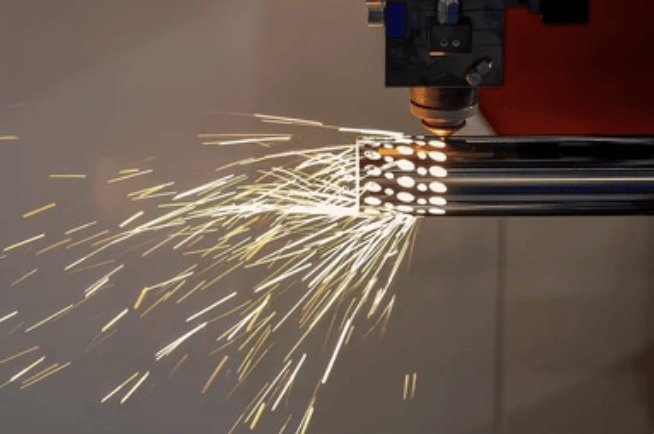

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Advantages Of Laser Cutting

Laser cutting is a highly precise and efficient method used across various industries for cutting a wide range of materials, including metals, plastics, wood, and glass. It offers excellent accuracy, smooth edges, and minimal material waste, making it ideal for intricate designs and high-quality finishes. The process is versatile, non-contact, and fast, with the ability to handle different thicknesses and materials. Additionally, it reduces the need for post-processing and enhances safety with automated and enclosed systems, making it a cost-effective and reliable cutting solution.

How Laser Cutting Works

1. Designing the Blueprint

・ A design is created using CAD software, specifying the exact dimensions, shapes, and patterns.

2. parameter setting

・ Cutting parameters, such as speed, power, and focus, are set based on the material type, thickness, and design complexity.

3. Material Setup

・ The material is placed on the laser cutter’s worktable, ensuring it is secure and properly aligned.

・ The machine’s software generates a cutting path based on the design, optimizing it to minimize waste.

4. Laser Beam Operation

・ The laser cutter uses a focused, high-energy beam to heat, melt, or vaporize the material along the designated path.

・ Assist gases (like oxygen, nitrogen, or air) blow away molten material to create clean cuts.

5. Cutting Execution

・ The CNC system guides the laser head precisely over the material, following the design with accuracy.

・ The process can include cutting, engraving, or marking, depending on the design requirements.

6. Post-Cutting Finishing

・ Any minor burrs or residues are cleaned up, although laser cutting typically minimizes the need for post-processing.

7. Quality Inspection

・ The cut components are inspected for accuracy, dimensions, and edge quality to ensure they meet design specifications.

Laser Cutting Materials

Laser cutting is suitable for a wide range of materials, including metals such as steel, stainless steel, aluminum, copper, and brass, as well as non-metals like wood, acrylic, plastics, glass, ceramics, and leather. It is also used for cutting advanced materials such as composites, rubber, and certain types of textiles.

Technical Guide for Laser Cutting

| Dimensional Tolerances ±0.1 mm to ±0.3 mm |

Kerf Width 0.1 mm to 0.3 mm |

Edge Precision Laser cutting provides smooth and burr-free edges |

| Hole Size Tolerance ±0.1 mm to ±0.2 mm |

Repeatability ±0.02 mm |

Thickness Limitations 25 mm |

| These are the usual standard tolerances. Specific tolerances can be further adjusted based on material properties and project requirements. | ||

Application

Laser cutting is widely used in industries such as automotive, aerospace, electronics, medical, construction, consumer goods, renewable energy, telecommunications, and packaging. Its key advantages include high precision, the ability to handle complex designs, minimal material waste, and versatility across a wide range of materials. This makes laser cutting ideal for producing intricate, high-quality components efficiently and cost-effectively.