CNC Turning

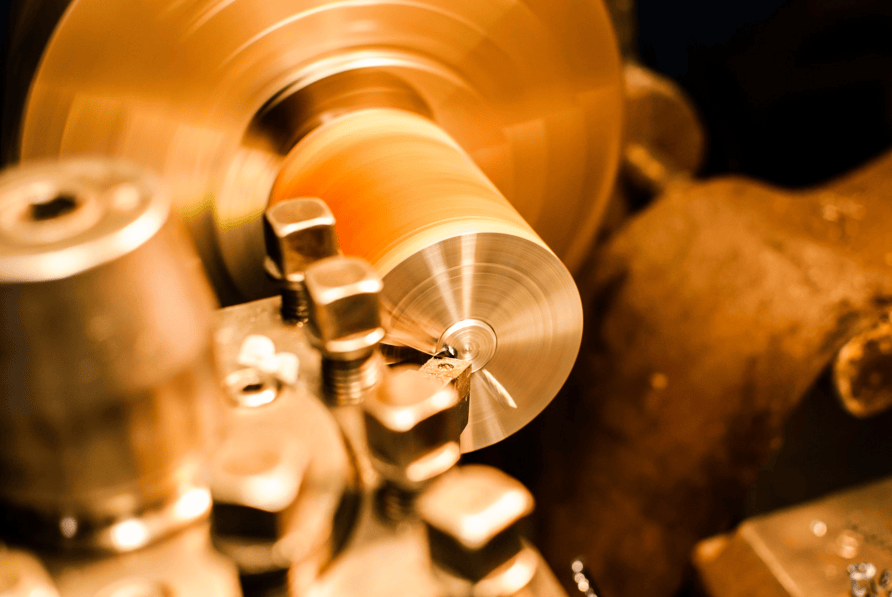

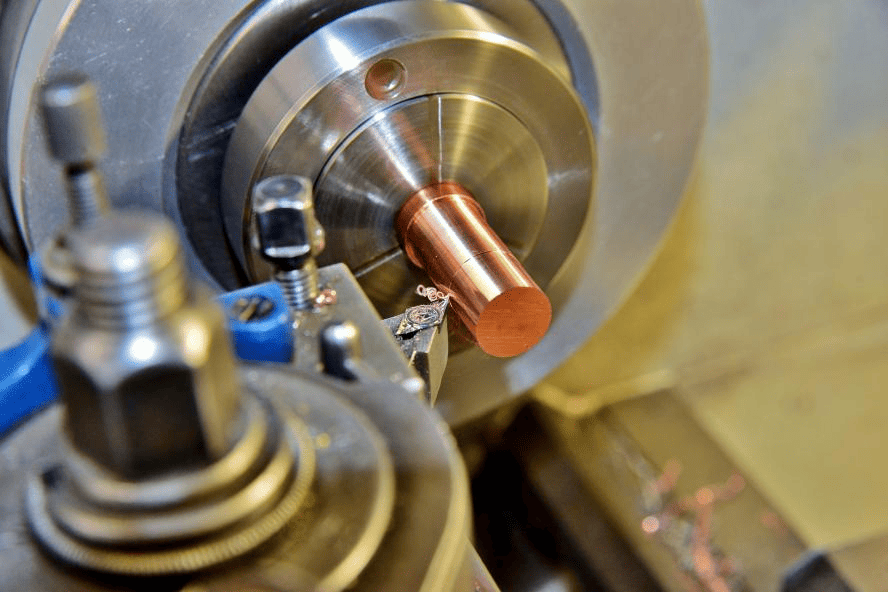

CNC Turning is a machining process that uses computer numerical control (CNC) technology to operate a lathe. The process involves rotating a workpiece while a cutting tool is applied to it, usually in a linear motion, to remove material and create cylindrical or conical shapes. The machine's movements are controlled by a computer program, which allows for precise and automated manufacturing.

- Overview

- Related Products

What is CNC Turning

CNC Turning is a machining process that uses computer numerical control (CNC) technology to operate a lathe. The process involves rotating a workpiece while a cutting tool is applied to it, usually in a linear motion, to remove material and create cylindrical or conical shapes. The machine's movements are controlled by a computer program, which allows for precise and automated manufacturing.

Key Characteristics of NAITE TECH CNC Turning:

1.Rotational Workpiece: In CNC turning, the workpiece is mounted on a spindle and rotated at high speeds, while a cutting tool moves along linear axes (usually X and Z axes) to shape the material.

2.High Precision: CNC turning can achieve high accuracy with tight tolerances, typically ranging from ±0.001 mm to ±0.005 mm, depending on the machine and material.

3.Suitable for Symmetrical Shapes: CNC turning is ideal for producing round or cylindrical parts such as shafts, rods, bushings, and discs. It's also used for producing tapered, grooved, or threaded parts.

4.Versatility in Materials: CNC turning can work with a wide range of materials, including metals like aluminum, stainless steel, brass, and titanium, as well as plastics and other non-metallic materials.

5.Efficiency: CNC turning allows for automated and high-speed production of parts, making it well-suited for both small and large production runs. It reduces the need for manual labor and increases production efficiency.

6.Complex Part Features: CNC turning can be combined with additional processes such as drilling, boring, and threading, allowing for the creation of complex geometries and detailed features in a single setup.

7.Minimal Waste: The precise control of cutting tools in CNC turning minimizes material waste, making it more cost-effective and environmentally friendly.

Applications of CNC Turning:

CNC turning is widely used in industries such as:

・Aerospace: For producing components like turbine blades and engine parts.

・Automotive: For creating parts like axles, brake discs, and engine shafts.

・Medical: For manufacturing items like surgical instruments and implants.

・Electronics: For making components like connectors, housings, and mechanical parts.

In summary, CNC Turning is a precise and efficient machining process used to create cylindrical, conical, or round parts, with high accuracy and minimal manual intervention. It is essential for producing complex, high-quality parts in various industries.

Feature

Front and back overlapped machining is possible with the back tool post.

Compact machine with back tool post with Y axis.Improves back machining capability.

・ Enhances machining capabilities by high output built-in motor equipped on the main and back spindle.

・ Maximum of 6 live tools can be mounted on the back tool post, and it can flexibly handle a variety of back machining needs

・ Reduces cycle time.

・ Live tool of front tool post (option) with max. speed of 10,000min-1 reduces the cycle time for small hole drilling.

|

Machine brand | B0205 |

| Max. machining dia | φ20mm | |

| Main spindle speed | Max.10,000min-1 | |

| (Normal rotation speed: 8,000min-1) | ||

| Back spindle speed | Max.12,000min-1 (normal rotation speed: 8,000min-1) | |

| Lool storage capacity | 21 PCS | |

| Rapid traverse rate | 36m/min (X2, Z2) 32m/min (Y1, Z1) 24m/min (X1) | |

| 15m/min (Y2) (Y2 axis is limited to 6-axis machines) | ||

| Main spindle motor | 3.7/5.5kW | |

| Back spindle motor | 2.2/3.7kW |

By selecting a tool post and tool unit and arranging them according to the machining process it enables many different kind of machining option.

・A unique slanted dovetail slideway structure for insreased rigidity of the tool post.

・4 types of tool posts are available to allow for a tooling layout most suited to the required machining applications.

・The guide bush/non-guide bush selector function ensures optimum machining for both long and short workpieces.

|

Machine brand | SB20R type G |

| Max. machining dia | φ20mm | |

| Main spindle speed | max.10,000min-1 | |

| 6 tools(□12mm) / 7 tools(□10mm) | ||

| Max.drilling capability | ø 12mm(1/2in) | |

| Max.tapping capability | M10×P1.5 | |

| Rapid feed rate | 35m/min(X1,Y1,Z1,X2,Z2) | |

| C-axis control | ||

| Number of tools | 4-10 tools(option is included) |

Achieving an ultimate low price for ø20mm machine

Providing a well-made composition, having all kinds of equipment and functions that are needed for machining as standard features

Achieving shorten cycle time by NAITE TECH own control method

|

Machine brand | A20VII |

| Max. machining dia | φ20mm | |

| Main spindle speed | max.10,000min-1 | |

| 200mm | ||

| Maximum tapping diameter for main spindle (tap,die) | M8 | |

| Maximum drilling diameter for rotary tool | 7mm Dia | |

| Maximum tapping diameter for rotary tool | M6 | |

| 21 | ||

| Tool size | 12mm Sq. (13mm Sq., 16mm Sq.) |