Surface Finishes

Surface finishes are treatments or coatings applied to materials to improve their appearance, functionality, or durability. These processes are crucial in enhancing the aesthetic appeal, corrosion resistance, wear resistance, and overall performance of the finished product. I'll give you an overview of some common processes.

- Overview

- Related Products

Surface finishes are treatments or coatings applied to materials to improve their appearance, functionality, or durability. These processes are crucial in enhancing the aesthetic appeal, corrosion resistance, wear resistance, and overall performance of the finished product. I'll give you an overview of some common processes.

Polishing

・Improves surface smoothness and gives a shiny or reflective appearance.

・Commonly used for decorative purposes or to reduce surface friction.

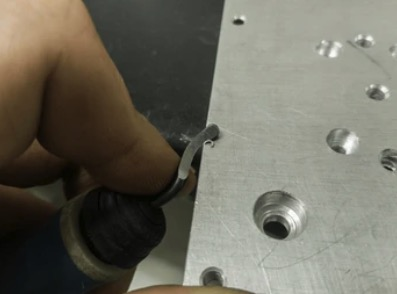

Deburring

・Removes sharp edges or burrs left from manufacturing processes like cutting or stamping.

・Ensures safety, improves aesthetics, and enhances assembly precision.

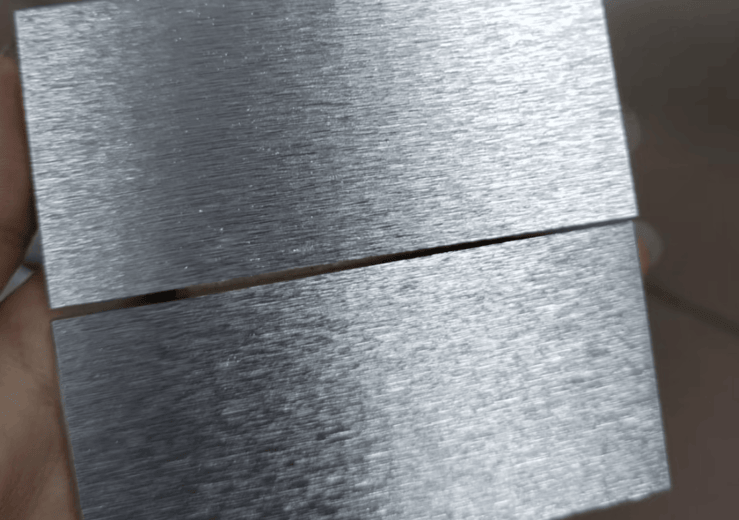

Wire Drawing/Brushed

・Produces a linear texture or pattern on the surface, giving it a matte finish.

・Reduces glare and adds a modern, industrial look.

Anodized

・An electrochemical process that creates a protective oxide layer, typically on aluminum.

・Increases corrosion resistance and allows for color customization.

Heat Treatment

・Alters the material’s microstructure to improve hardness, strength, or durability.

・Common processes include annealing, quenching, and tempering.

Chrome Plating

・Applies a thin layer of chromium to enhance corrosion resistance, wear resistance, and shine.

・Often used in automotive and decorative applications.

Nickel Plating

・Provides corrosion resistance and wear protection with a bright or satin finish.

・Common in electronics and machinery parts.

Tin Plating

・Coats surfaces with a layer of tin to prevent oxidation and improve solderability.

・Frequently used in the electronics and food packaging industries.

Silver Plating

・Adds a thin silver layer for conductivity, corrosion resistance, or aesthetic purposes.

・Ideal for electrical connectors and decorative items.

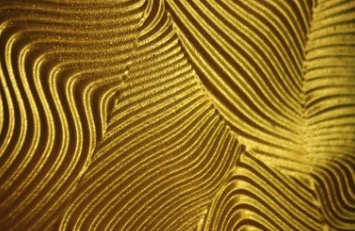

Gold Plating

・Offers excellent electrical conductivity, corrosion resistance, and a luxurious appearance.

・Common in electronics and jewelry.

Galvanizing

・Coats steel or iron with zinc to prevent rust and corrosion.

・Commonly used in construction and outdoor applications.

Blackening

・A chemical process that creates a black oxide layer, improving corrosion resistance and reducing glare.

・Often applied to tools, firearms, and machinery parts.

Customization

Surface finishes can be customized to meet specific customer requirements, balancing functionality and aesthetics for the intended application.

If you want to know more details and process, please contact us!