การผลิตการกลึง

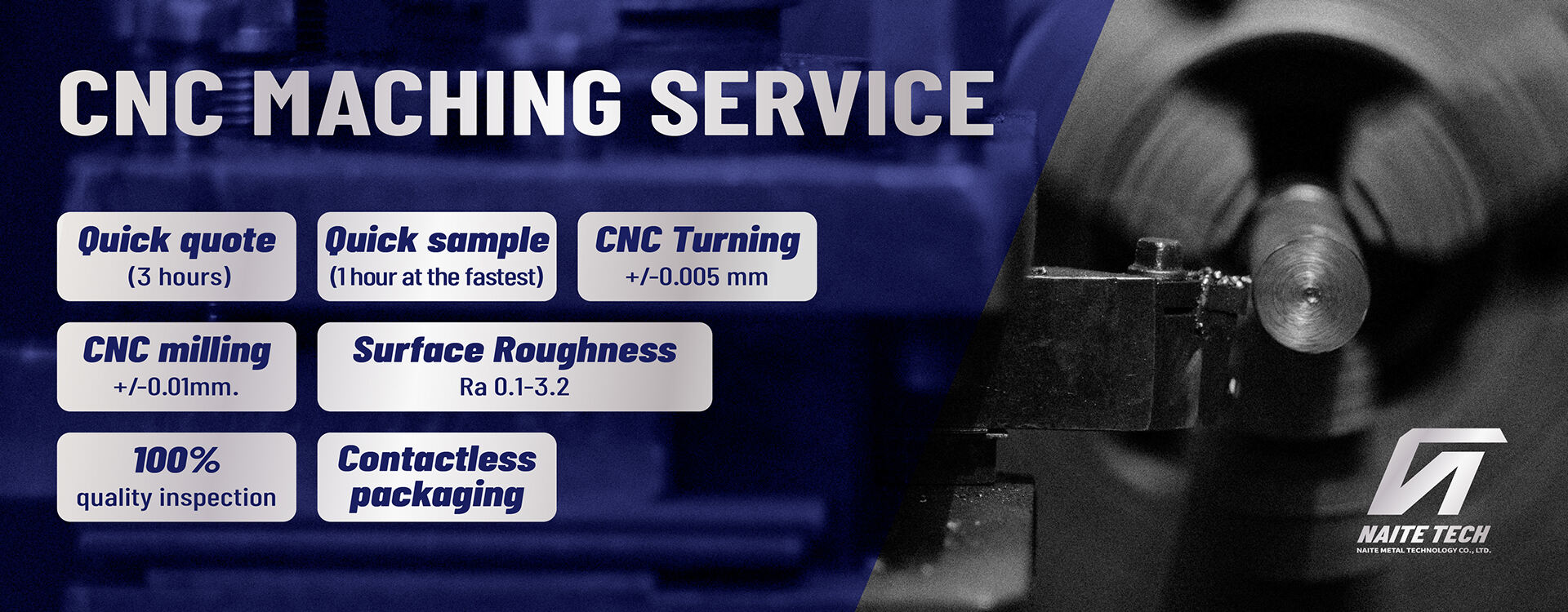

การผลิตด้วยการกลึงเป็นกระบวนการที่มีความแม่นยำซึ่งเกี่ยวข้องกับการใช้เครื่องมือกลเพื่อเอาวัสดุออกจากชิ้นงานเพื่อสร้างรูปร่าง ขนาด และพื้นผิวที่ต้องการ ฟังก์ชันหลักของการกลึงรวมถึงการตัด การหมุน การกัด การเจาะ และการขัด เทคโนโลยีที่มีอยู่ในกระบวนการผลิตด้วยการกลึงสมัยใหม่รวมถึงระบบควบคุมเชิงตัวเลขด้วยคอมพิวเตอร์ (CNC) ซึ่งให้ความแม่นยำและความสม่ำเสมอสูง รวมถึงความสามารถในการผลิตรูปร่างและส่วนประกอบที่ซับซ้อน กระบวนการเหล่านี้มีความสำคัญในอุตสาหกรรมต่างๆ เช่น ยานยนต์ อวกาศ และการแพทย์ ซึ่งความแม่นยำและคุณภาพสูงมีความสำคัญยิ่ง การใช้งานการผลิตด้วยการกลึงมีตั้งแต่การสร้างชิ้นส่วนขนาดเล็กที่ซับซ้อนสำหรับอิเล็กทรอนิกส์ไปจนถึงส่วนประกอบโครงสร้างขนาดใหญ่สำหรับเครื่องจักรหนัก